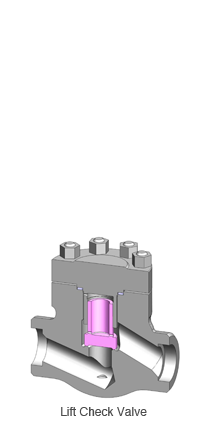

We typically call for less than 50 A diameter, that we confirmed by the corresponding valve forged steel lift check valve casing.

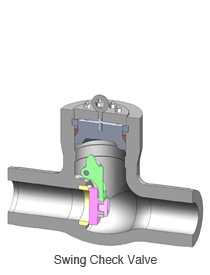

| Name | Swing Check Valve |

| Body Material | ASTM, ASME, JIS, Cast Steel / Forged Steel Carbon Steel, 1Cr0.5Mo Steel, 2.5Cr1Mo Steel, Stainless Steel, 9Cr1Mo-V Steel, etc. |

| Fluid | Water, Steam, Gas, Oil etc. |

| Pressure Class, Size(Standardized) | Class 150 - 2500: 65 mm - 60 mm Class 3500: 65 - 400 mm Class 4500: 65 - 300 mm For 50 mm and smaller size, lift check type is adopted as our standard. |

| Connection Form | Socket weld, butt weld, flanged* |

| Name | Lift Check Valve |

| Body Material | ASTM, ASME, JIS, Cast Steel / Forged Steel Carbon Steel, 1Cr0.5Mo Steel, 2.5Cr1Mo Steel, Stainless Steel, 9Cr1Mo-V Steel, etc. |

| Fluid | Water, Steam, Gas, Oil etc. |

| Pressure Class, Size(Standardized) | Class 150 - 2500:- 400 mm Class 3500 - 4500:- 150 mm |

| Connection Form | Socket weld, butt weld, flanged* |

*For valves with flanged connection, indicate the surface shape (raised face, flat face, etc.) for each flange standard (ASME, JIS, etc.)

• The above specifications are for standard products. Please inquire for other specifications..

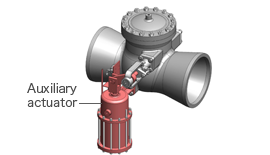

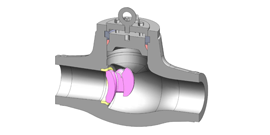

Tilting disc check valves, which have a more specialized configuration than normal swing check valves, and valves with an auxiliary actuator are some examples.

This is a type of swing check valve that comes equipped with an auxiliary actuator to enable external valve operation for various applications.

The extraction check valve shown on the left is one example. This valve adds driving force in the direction of valve closure when air is bled from the cylinder on a turbine trip.

The tilting disc check valve is designed to shorten valve closure time compared to the normal swing check valve, thereby minimizing the increase in water hammer pressure when the valve is closed.

Although the two types of valves adapt the same hinge mechanism, the tilting disc check valve is structurally different from the normal swing check valve in that its axis of rotation is immersed in the flow of fluid and that it has conical seating surfaces, among other differences.